_1400x400.jpg)

Business engagement

Through mutually beneficial partnerships with businesses and SMEs, we work with industry to make a positive societal impact.

From allowing our equipment and facilities to be used for research to carrying out commissioned research, our highly skilled members have a lot to offer.

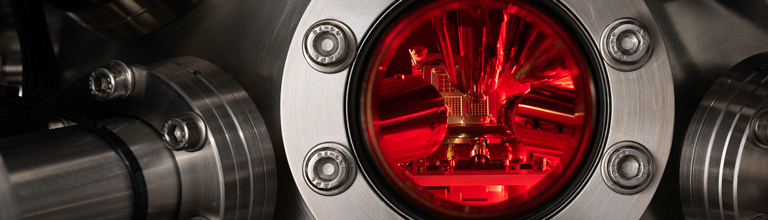

Facilities

We can arrange for the commercial use of our leading facilities, which are ideal for supporting industrial and applied research into new material systems.

Recruiting our graduates

We host more than 70 postgraduate and postdoctoral students who are recruited by Departments within The University of Manchester who pursue research in the PSI. As a business, you can advertise vacancies through the University's Careers Link service.

Case studies

Working with us can benefit businesses in a number of ways. Below are some examples of when collaborating with us has led to profitable results.

Case study: Huntsman Polyurethanes

As part of an industrially funded PhD studentship, specific EPR measurements were undertaken at the EPR Service in Manchester which provided new information that was highly relevant to the optimisation of a large-scale chemical manufacturing process chain.

David Lennon (University of Glasgow, GU) has an ongoing research relationship with Huntsman Polyurethanes regards investigating certain fundamental physico-chemical matters connected with the large-scale manufacture of isocyanates. These chemicals are used in the production of polyurethane compounds, which have wide application in society (eg automotives, construction, insulation, etc). In 2006, David commenced a Huntsman sponsored PhD studentship at GU to investigate the origins of impurities that can form in certain large-scale isocyanate production processes. Specifically, the project sought to investigate the chemistry of certain aromatic isocyanide dichlorides. It was speculated that in the process environment these molecules could lead to by-products that compromise product purity.

This particular problem required the application of EPR to establish whether aryl dichlorides could behave as a chlorine radical source under relevant conditions. The EPR National Service (based in the Photon Science Institute) provided the hardware and expertise to address this specific problem. They also provided high-level training to the PhD student (June Callison). On the basis of the EPR measurements conducted in Manchester, the GU team were able to understand the chemistry connected with the by-product formation and to communicate this to their industrial collaborators.

The resulting heightened awareness of aspects of the commercial process operation has assisted the company to optimise the atom economy of their large-scale unit operations. This advancement would not have been possible without the considerable expertise of the National EPR Service.

Key outputs of this relationship have been:

- new knowledge;

- improved understanding of a large scale chemical manufacturing process;

- optimisation of the manufacturing process;

- high quality training of PhD students in the application of EPR spectroscopy;

- two high quality publications.

Case study: Laser Quantum

Formed in the 1990s by three PhD physicists from The University of Manchester, Laser Quantum has grown into a company that is globally recognised for the quality, reliability and the scientific advances it brings to the photonics market. It produces over 3,000 lasers per year including both diode pumped solid state (DPSS) and Ti:Sapphire ultrafast lasers at its headquarters in Stockport and its subsidiaries in Konstanz and Hannover, Germany and San Jose in California, USA. With a turnover in excess of £12 million and over 100 employees, Laser Quantum continues to grow and expand its product portfolio and application base.

Laser Quantum Ltd. continues to maintain strong links with The University of Manchester through on-going collaborative projects with researchers at the Photon Science Institute. Recently they were awarded a £33k EPSRC Impact Acceleration Grant titled "Breaking the Frequency Barrier: Pushing Magnetic Resonance Technology into the Terahertz Regime" a collaboration between Dr Albrecht Bartels (Laser Quantum) and Dr Darren Graham from the Department of Physics and Astronomy. The grant is focused on investigating the commercial potential of several research developments within the field of terahertz spectroscopy, including the terahertz asynchronous optical sampling technique pioneered by Dr Bartels.

More information

- Case study: Spin-out research companies create new laser technologies worth £30 million (Department of Physics and Astronomy website)

- Laser Quantum website

Case study: Lynton Lasers

Lynton Lasers Ltd produce laser-based equipment for aesthetic and cosmetic surgery, such as tattoo and hair removal, and the treatment of vascular lesions. They have a 12% share of the Intense Pulse Light (IPL) market, but also produce a range of high end lasers.

In addition to marketing their products, they also operate a very successful clinic applying the techniques to patients and clients. To support this they run a highly respected range of training courses (in Manchester and London) as refreshers or for those wishing to enter into the laser aesthetic and cosmetic industry.

Members of the Photon Science Institute help run these courses and disseminate the very latest research findings on medical laser techniques to the clinicians and healthcare workers.

Lynton Lasers employs around 30 people, has 600 systems in the field and has an annual turnover of £5.3 million.

Each year Lynton Lasers' systems are used to treat over 10,000 patients; these treatments generate turnover in the region of £6 million every year for private clinics and treatment centres.

More information

- Case study: Spin-out research companies create new laser technologies worth £30 million (Department of Physics and Astronomy website)

- Lynton Lasers website